Informazioni di Base.

Model No.

Air Compressor

Stato

nuovo

Certificazione

ISO, CE

purezza dell′azoto

99.99%

Pacchetto di Trasporto

The Wood Box

Specifiche

according to requirement

Marchio

OEM

Origine

Jiangsu, China

Codice SA

841960909

Capacità di Produzione

500sets/Years

Descrizione del Prodotto

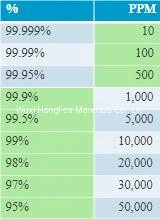

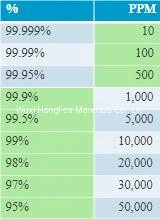

Equipment selection table:

Nitrogen purity: 95%~99.999

Nitrogen pressure: 0.01~ 0.8mpa

Nitrogen dew point: -40 ºC~ -60 ºC

Product Features:

It has the characteristics of simple process, high degree of automation, fast gas production (15 ~ 30 minutes), low energy consumption, product purity can be adjusted in a large range according to user needs, convenient operation and maintenance, low operating cost, strong adaptability of the device and so on. | Nitrogen purity | 99% | 99.5 | 99.9% | 99.99% | 99.999% | Intel | Outlet | Boundary Dimension |

| Air specific weight | 2.8:1 | 3:1 | 3.8:1 | 5:1 | 7:1 | Diameter | Diameter | L×W×H(mm) |

| SPN-1 | 5 | 3 | 2 | 1.5 | 1 | DN15 | DN15 | 800*650*1240 |

| SPN-2 | 10 | 6 | 5 | 3 | 1.5 | DN15 | DN15 | 800*650*1720 |

| SPN-3X | 20 | 15 | 10 | 5 | 3 | DN15 | DN15 | 420*900*1750 |

| SPN-4X | 30 | 25 | 20 | 10 | 5 | DN20 | DN15 | 1200*600*1845 |

| SPN-5X | -- | -- | 30 | 20 | 10 | DN20 | DN15 | 1200*600*1845 |

| SPN-6X | -- | -- | 40 | 25 | 15 | DN25 | DN15 | 1360*1100*1870 |

| SPN-7 | -- | -- | 50 | 30 | 20 | DN25 | DN20 | 1360*1350*2200 |

| SPN-8 | -- | -- | 60 | 40 | 25 | DN40 | DN25 | 1500*1350*2200 |

| SPN-9 | -- | -- | 80 | 50 | 30 | DN40 | DN25 | 1500*1350*2200 |

| SPN-10 | -- | -- | 100 | 60 | 40 | DN40 | DN40 | 1550*1450*2200 |

Technical indicators:

Nitrogen production: 1~3000Nm3/hr Nitrogen purity: 95%~99.999

Nitrogen pressure: 0.01~ 0.8mpa

Nitrogen dew point: -40 ºC~ -60 ºC

Product Features:

Workflow:

Clean compressed air enters from the bottom of the adsorption tower filled with carbon molecular sieve. After the air flow diffuses through the special structure of the equal distribution diffuser, it uniformly enters the adsorption tower for oxygen and nitrogen adsorption and separation. Then, high purity nitrogen is produced from the top of the adsorption tower and sent to the nitrogen process tank for storage. A small amount of finished nitrogen enters the regeneration tower to blow and wash the carbon molecular sieve, removing the adsorbed oxygen to achieve regeneration. The two adsorption towers operate in alternate cycles, continuously feeding raw air and continuously producing nitrogen.

Application Industry:

Products widely usedIt can be widely used in all walks of lifeIt is suitable for photovoltaic industry, petrochemical industry, metallurgy industry, coal industry, rubber tire industry, environmental protection industry, pharmaceutical industry, electronics, semiconductor, SMT industry, new energy lithium industry, chemical fiber industry and other fields.